Value chain and applications

Making textile recycling an industrial and circular reality

Refashion is seeking to transform the end-of-life management of clothing, household linen and footwear (CHF), creating a circular, competitive, sustainable and resilient ecosystem that is part of a broader industrial dynamic spanning France and Europe.

In this section, you can find out more about the different stages in the textile recycling value chain, the key players and the wide range of potential applications.

A shared ambition

Our guiding principles are to prevent and treat waste and to reduce its impact. Our goal is to reduce environmental impact and make the circular economy tangible and measurable.

R&D: Innovation and expertise to drive the industry forwards

Study and test

Research and development are key to the industry's transformation. Refashion supports and coordinates projects that aim to:

- Study and test waste reduction solutions

- Valorize all resource streams, regardless of materials or product types

Innovation is the driving force behind circularity: this is how we will make the leap from prototyping to industrial production.

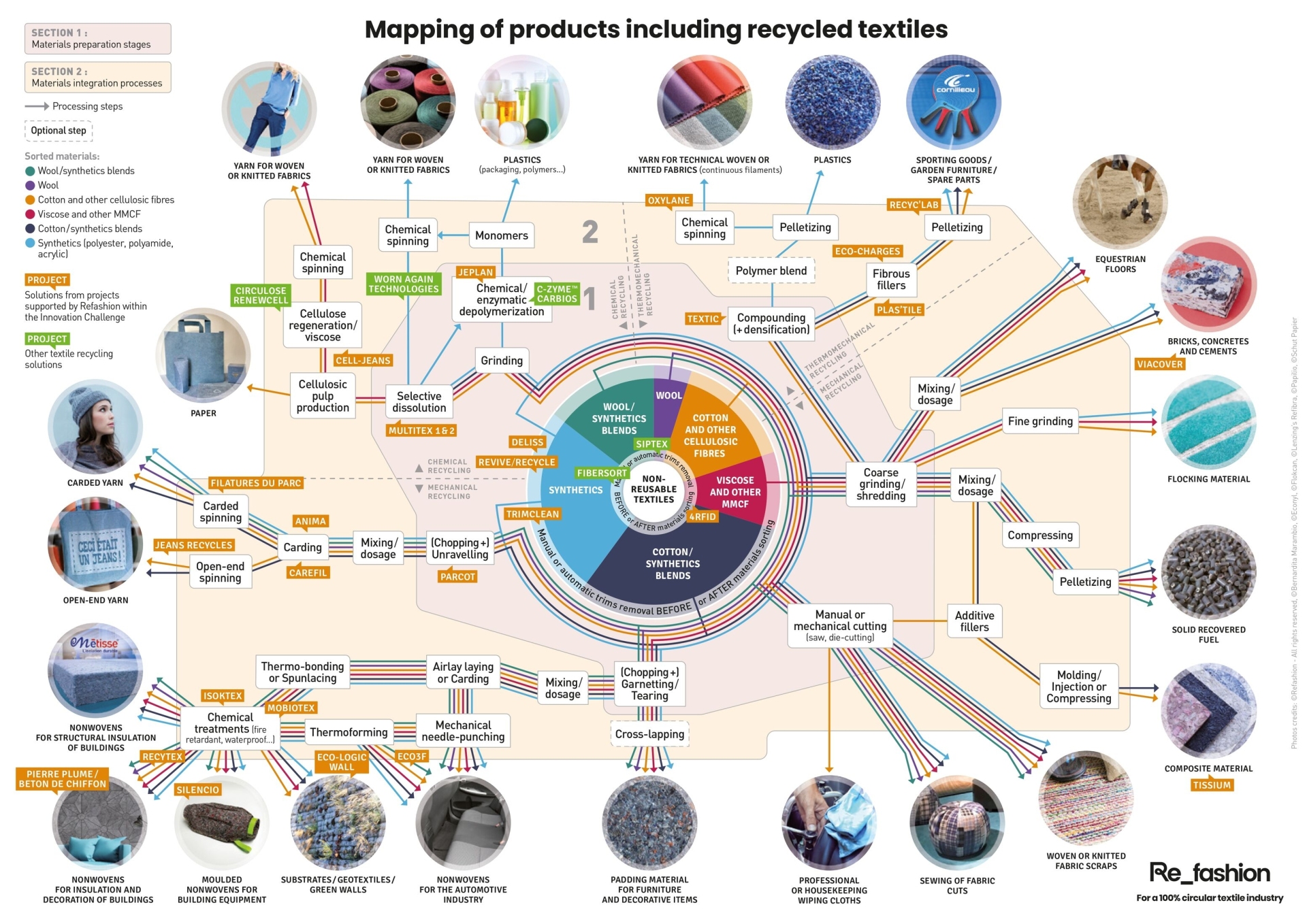

Specific applications for a circular process

The second-hand market in France and Europe

Refashion supports the development of a local second-hand market to increasingly replace new CHF and also to reduce imports of second-hand clothing.

This momentum is underpinned by the development of reconditioning and resale across European markets.

Recycling on an industrial scale

The challenge is to build a competitive industrial base, able to absorb and recycle huge quantities of used textiles and footwear.

This will require:

- Advanced technologies tailored to post-consumer CHF

- Smooth logistics connecting all the links in the chain

- Recycled materials meeting the needs of manufacturers at a viable cost

Making textile recycling a sustainable industrial reality means building an industrial base that is able to create value and jobs and that has a positive impact.

Who are the players in the value chain?

Each player is active in driving the industry forward:

Sorting operators

Identify, sort and channel waste streams

Material preprocessors

Conduct advanced sorting, remove disruptors and prepare materials for recycling

Technology suppliers

Develop appropriate processes and equipment to automate and optimise the stages of sorting and material preparation

Recyclers

Turn textile and footwear waste into new materials using mechanical, thermomechanical or chemical processes

Closed-loop integrators

Spinners, weavers, knitters, garment makers and sole manufacturers who include recycled materials in their products

Open-loop integrators

Plastics manufacturers, manufacturers of insulation and non-woven fabrics, furniture panels and other miscellaneous products using recycled materials for new applications.

Join Refashion's recycle platform and find out more about the players in recycling

Register / LoginMultiple applications

Recycled materials can be used in a number of sectors:

- Cleaning cloths for industry

- Thermal and acoustic insulation for the automotive and construction industries

- Panels or composites for furnishings

- New yarns through spinning (long fibres, single material) for the clothing industry

- Applications involving plastics and composite materials

- New soles for footwear

Challenges to be addressed together

Key levers to successfully transform the textile recycling industry:

- Waste resources of sufficient quality and quantity

- Robust technologies suitable for post-consumer textiles and footwear

- Efficient logistics connecting every link in the chain

- And an economically competitive approach to ensure the viability of the recycled materials for manufacturers

The key to success: a collective effort, driven by coordinated investment, collaborative projects and a commitment shared by all the players in the value chain.

To go further

Discover the recycling value chain

When reuse, repair or re-use are no longer an option, recycling becomes the key to prolonging the life of textile materials and offering them new outlets.

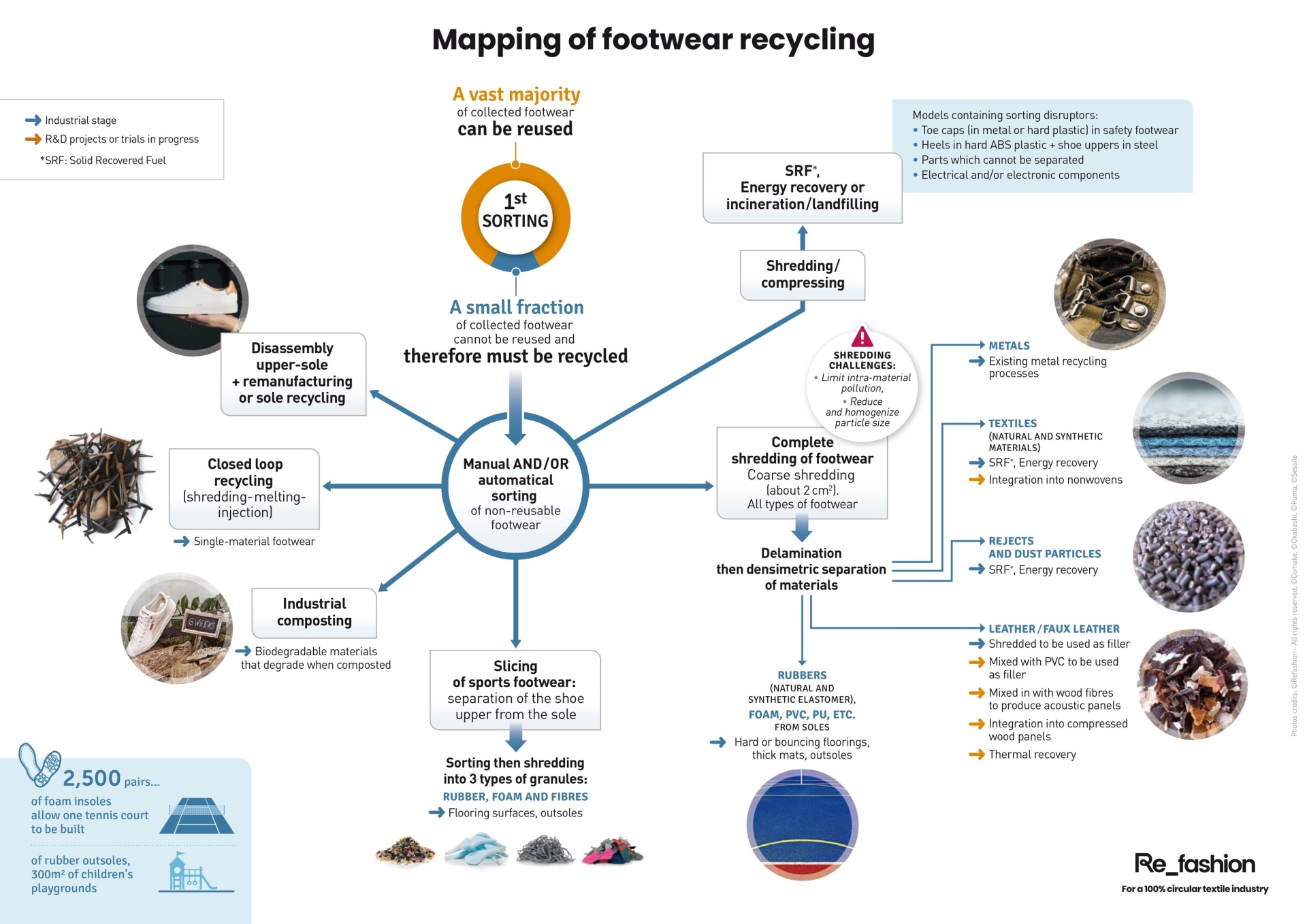

Explore our page dedicated to shoe recycling

While textiles can be recycled in a variety of ways, footwear recycling presents different challenges. Indeed, footwear is an extremely complex product, due to the different elements that make it up.

Dive into sorting and material preparation

We explain the stakes, technological challenges and innovative solutions for optimizing the quality of recycled materials.