The Recycle Platform: 5 years supporting textile/footwear recycling stakeholders across Europe

Recycle by Refashion is a European digital platform that connects professionals involved in the recycling !

Recycle by Refashion is a European digital platform that connects professionals involved in the recycling !

In 2023, Refashion explores the second-hand TLC market in France. A revealing study of a fast-changing sector, driving more sustainable fashion.

Supported by the French Climate and Resilience Act, environmental labelling is an ambitious project aimed at informing consumers about the ecological impact of the products they buy, encouraging businesses to reduce their environmental footprint, and promoting more responsible consumption. Discover the latest news here.

Today, 31.4% of the textile and footwear products put on the market are collected in the Voluntary Drop-off Points (VDP), approved by Refashion, to integrate a sorting process. Find all the VDP on the mapping of Refashion

To encourage citizens to do the right sorting, the French law against waste and for the circular economy requires the presence of a sorting info on textile and footwear products from February 2023. To find out more, see our article.

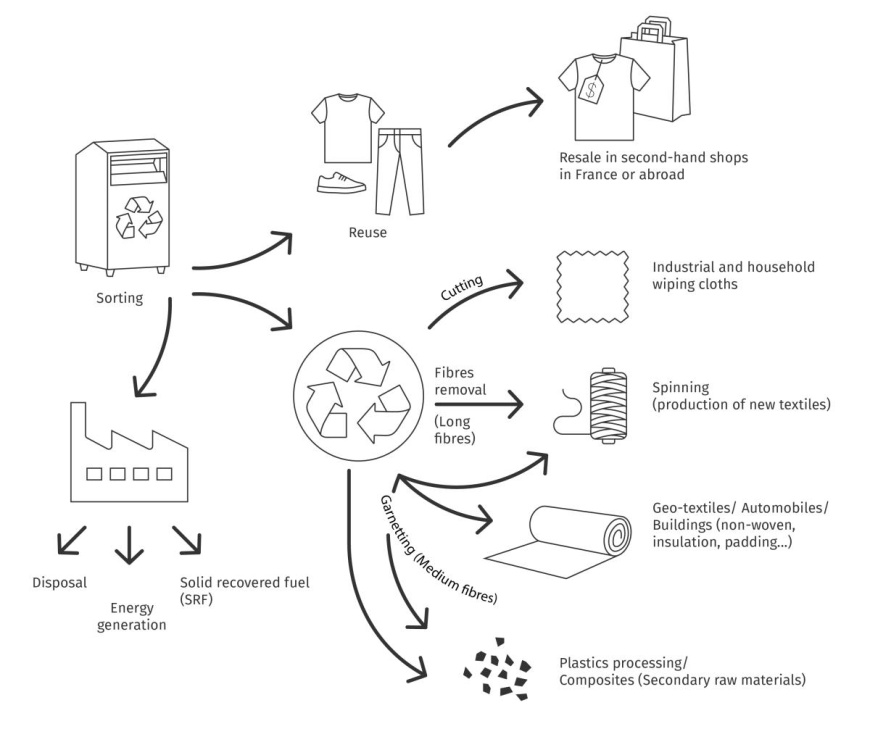

Once textiles and shoes are collected, there are several recovery modes exist for these products : reuse (59.5% of collection), recycling (31.3% of collection) and energy recovery (8.7% of collection). Only 0.5% of the items collected are discarded.

Consequently, the end-of-life CHF (Clothing, Household linen and Footwear) sector is tending towards a circular dynamic, namely thanks to ever-sophisticated recycling and recovery techniques. These techniques differ according to the product and its composition. Charts have consequently been compiled for textiles and footwear.

There are two different types of recycling: open loop and closed loop. Open loop recycling consists in using recycled material for a different purpose but in order to replace a virgin raw material (recycling of a PET bottle into fleece fibre for example).

Closed loop recycling consists in using recycled raw material for an identical purpose and use, without a functional loss of material (using the material recycled from a pair of jeans to make a new pair of jeans for example). Closed loop recycling is therefore a more circular type of recycling.

A possible solution in order to avoid discarding textiles and footwear when they cannot be recycled is energy generation. One of the main solutions is that of Solid Recovered Fuel (SRF). This consists in shavings manufactured from the non-recyclable fraction of waste (non-hazardous) which are used by industry players (namely in the cement industry) owing to their high calorific power, as a replacement to conventional fossil fuels (fuel and gas for example). SRF are mostly composed of paper, cardboard, wood, plastic and textiles. Energy generation is therefore an alternative to landfill or incineration.

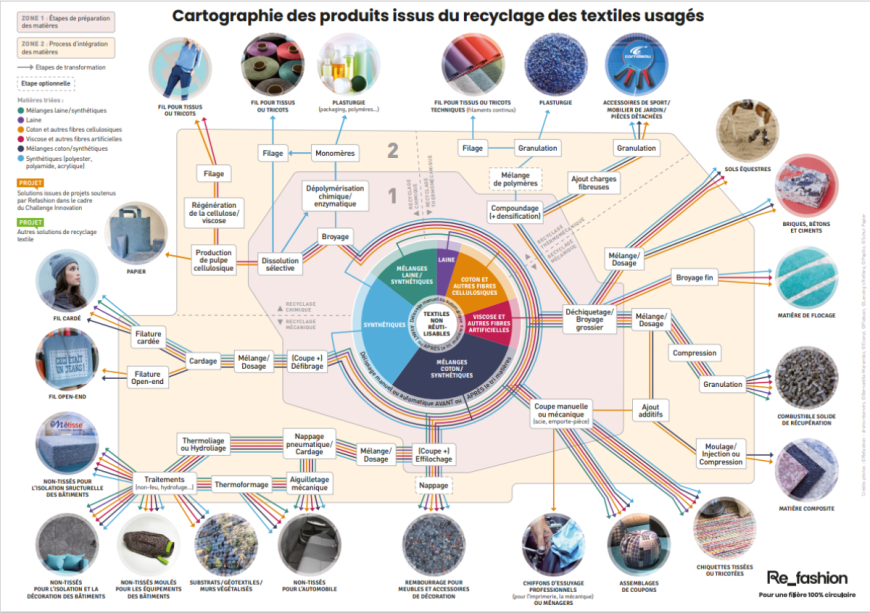

Textile recycling outlets depend on the composition of the material to be recycled (synthetic materials, cellulose materials, blends...). Recycling processes to obtain a new product are therefore just as numerous as the outlets. We can distinguish between two types of recycling processes: mechanical recycling and chemical recycling.

Download the Mapping of products including recycled textiles

Whilst these technologies are not yet mature and their processes not yet profitable, numerous experiments are in progress.

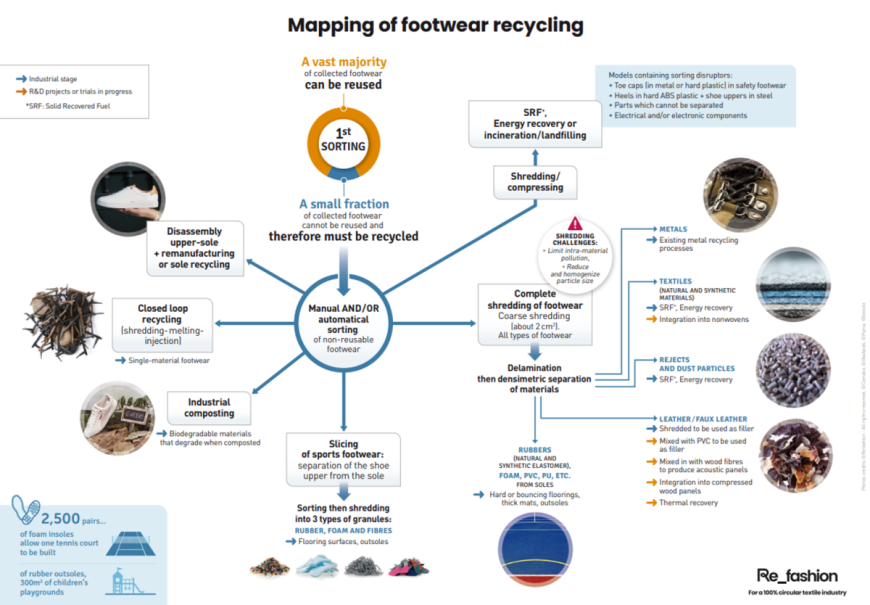

Conversely to textile recycling processes, used footwear recycling solutions are few and far between, namely owing to the complexity of the products and the plurality of the materials used. The separation of materials with a view to their recycling is therefore a veritable problem. Some recycling solutions do exist however :

Le Shredding : coarse tearing of the entire shoe then separation of materials in order to recycle them (rubber is used to make soles for example or to create a floor covering)..

Le Cutting by slicing : to separate the upper shoe from the sole. Materials are then sorted (rubber, foam and fibres) and transformed into pellets to make new soles or to create a floor covering.

Le Industrial composting : biodegradable materials can be transformed into compost.

Download the Mapping of footwear recycling

Many elements on products, textiles and also shoes, disrupt recycling. These elements can be internal or external to the products. They are commonly referred to as "hard points". These elements disrupt or even prevent the recycling of products. Indeed, their presence can not only degrade the recycling equipment but also leave impurities in the recycled material.

It is essential to eco-design products and limit disruptors (internal and external) in order to facilitate the recycling of materials. To improve the recyclability of your products there are a few basic principles you can apply.

Source : Study on disruptors and facilitators of textile recycling, ENSAIT, 2014

Reduce the use of metallic parts;

Limit the use of solid plastic parts;

Limit the mixture of different material types;

Consider the material density to ease their separation;

Reduce the use of adhesives where possible;

Labelling of the main material types;

Avoid non removable electronics components.

Source : Footwear eco-design guidelines to improve recyclability, AIR and SOEX, 2018

Thank you for your confidence